HOME > PRODUCTS > Safety And Environment Monitor > Anti-overfill Valve And Controller

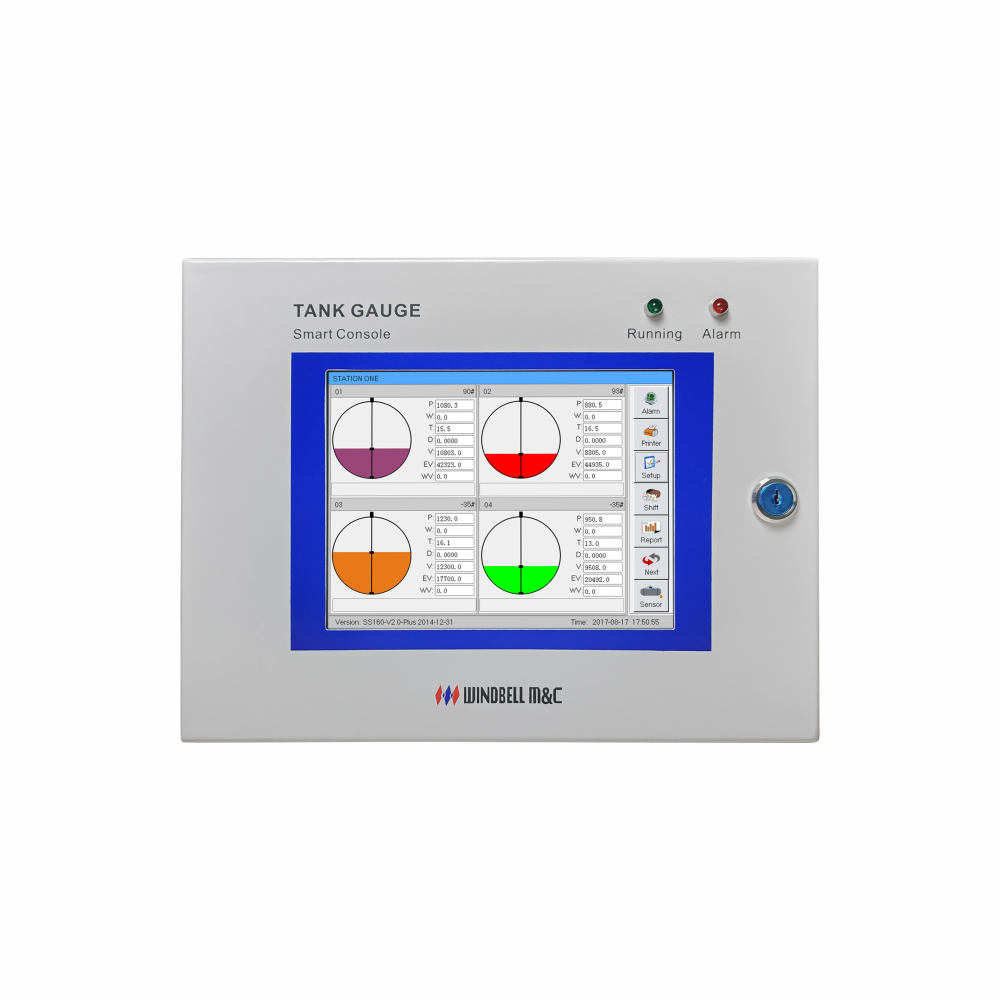

It is composed of two parts: valve controller and anti-overflow valve. The valve is installed at the loading pipe between oil truck and underground tank.

When unloading oil, the ATG monitors the oil level in real time. When the oil level of the oil tank reaches the preset oil level alarm, ATG console sends a control signal to the anti-overflow valve controller, and then controls the anti-overflow valve to automatically cut off the oil inlet path within 1~2 seconds, so as to achieve the purpose of oil spill prevention.

Anti-overfill Valve And Controller

-

When the oil height arrive the alarm value of Oil High (e.g. 90%), the valve can automatically trigger alarm; when the oil height reach to the alarm value of Oil HH (e.g. 95%), it will cut off the loading pipe automatically, so to protect against overfill perfectly.

Usually user preset the alarm value of Oil H and Oil HH in console, when the oil level data from SP300 magnetostrictive probe reach to this alarm valve, console will send demand to valve controller instantly. The data transmission speed from probe to console is one time per ms; all demands transmission and cut off will be finished in seconds, much faster than manually operation.

Item Parameters Model DFVC Anti-overfill Controller Power

AC200V +/- 10% Comm. port

RS485

Monitor up to

6 valves

Dimension

28*21*10cm

Item Parameters Model

DFV100 Anti-overfill Valve Rated voltage

DC220V, <5A

Rated current

1.5A

Respond speed

1-2s

Ex-proof mark

Exd IIA T4 Gb

Protection grade

IP66

Specification for select

DFV100-DN65, DFV100-DN80, DFV100-DN100

All right reserved © Zhengzhou Windbell Measurement and Control Technology Co., Ltd